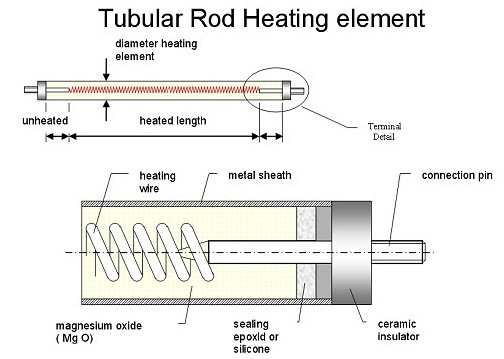

The most versatile of all electric heating elements, the tubular heater is capable of being formed into virtually any configuration. The basic design consists of a helical coil of nickel-chromium resistance wire precisely centered in a metal sheath. This coil is surrounded by magnesium oxide powder which is vibration loaded to insure even density throughout the length of the heater. This entire assembly is then reduced to the finished diameter, compacting the MgO and “freezing” the coil in the center of the heater. The range of ratings, sizes, materials and terminations available makes the tubular heater adaptable to many industrial, commercial and scientific applications.

Precision Wound Resistance Wire

Nickel Chromium coiled resistor (computer designed). Precisely wound to provide exact heat requirement. Each individual spiral being thoroughly chemically washed to eliminate contamination and give a longer element life.

Welded Connection

The connection between terminal pin and resistor is securely made by electronic welding or crimping.

Electrical Insulation

The resistor coil is centrally located during manufacture and insulated with high purity Magnesium oxide powder. When compacted by rolling or swaging, the magnesium oxide powder provides excellent thermal conductivity and dielectric strength.

Sheath Material

A selection of sheath material is available depending on individual customer’s requirements and applications. (Please see chart for options). All heaters are fully annealed to allow forming.

Sealing

All heaters are sealed during manufacture to protect against moisture absorption during storage. This will not however serve to protect against liquid infiltration and chemical attack. Various sealants are available for special conditions. Please consult factory for further assistance if you require any special needs.

Insulation and Threaded Terminals

Ceramic or mica insulators ensure the electrical insulation of the terminal stud from the sheath. The standard threaded stud provides a quick and easy termination. However, a large selection of termination options is available